My concrete basement floor is very uneven, and so my laundry washer and dryer were bouncing all over the place. I solved this problem by making an inexpensive pedestal for my laundry machines. This post is about how I designed and made my laundry pedestal. It cost me less than $25 to make, and took about 30 minutes to build.

A pedestal has numerous benefits:

- It gives the equipment a perfectly level surface to sit on.

- It raises the machines so that they are easier to access.

- If there is a basement flood, a pedestal raises the machines out of harm's way

- It is very inexpensive. I made mine for about $25 in materials.

Laundry Pedestal Design

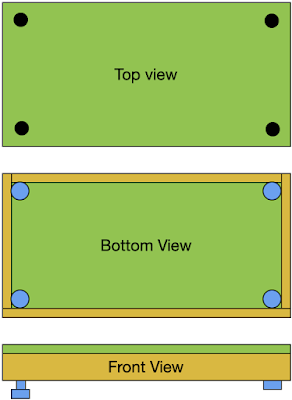

My pedestal is basically a piece of 3/4 inch plywood with an underlying frame made of 2x4 lumber around it to give it some structure. Then I mounted robust adjustable feet on each corner. In order to easily adjust the feet while the platform was sitting on the floor, I drilled four holes in each of the corners, directly above the adjusters. These holes let me adjust the feet with a hex wrench.

|

| Figure 1: Three views of my platform design (not to scale) |

Materials Required

- A sheet of 4x8 plywood, cut down to the desired size

- Some 2x4 lumber, cut to size

- Four adjustable feet

- Some screws

Tools Required

- Wood saw

- Power drill

- Screwdriver

- Level

Construction Process

- Go to lumber store and get a 4x8 sheet of 1/2 inch or 3/4 inch plywood.

- If you are like me, it is a pain to transport a full sheet of plywood, and it is a pain to cut it at home. Most stores will cut it on their panel cutter for free - very fast, very straight, and no sawdust mess to clean up. I had them make two cuts, so I ended up with one 3 foot x 5 foot platform - big enough for the two machines side-by-side and plenty of depth, and small enough to fit into the back seat of my car. I also ended up with some useful scrap pieces of plywood (1x5 feet & 3x4 feet) for future projects.

- Get three 8 foot 2x4.

- Bring it all home.

- Add the bracing made out of 2x4 lumber, mounted around the perimeter of the board. This structure prevents the panel from flexing. Note that the weight of the machines is generally around the perimeter and not in the center. Screw the 2x4 braces to the board using appropriate screws. Optionally, glue together in order to make the structure more rigid. Optionally, add more 2x4 bracing to the bottom to make more rigid / less flexible.

- Get some hefty steel adjustable feet, like these from Amazon. Screw them to the corners of the structure.

- Place the platform. Using the adjustable feet, make it perfectly level. Once set, I used both locknuts and locktite on the adjusters to help ensure that vibration doesn't cause them to turn on their own.

- Adjust the laundry equipment feet so they're all level too. Put the equipment on top. Double check that everything is nice and level.

- I fashioned a brace to prevent the entire platform from shifting on the floor if the machine loads become unbalanced.

- I also fashioned a removable lip around the unprotected edges, in case the washer starts to work its way towards the edge and fall off. I made the lip removable in the case I want to pull off the washer for maintenance/repair/replacement.

Since my platform is in the basement, I didn't paint it. I suppose one can paint or stain it for protection and/or style. I didn't bother. I'm pretty sure it'll outlast me even without paint.

That's it! Have fun!