I repair A1342 MacBooks, and so I know them quite well. They can be wonderful machines, even in 2018. Here is my advice for the diagnosis and repair of the A1342 series of machines.

Brief Overview

The A1342 is the only polycarbonate Unibody MacBook. There are two revisions: late 2009, and mid-2010. These revisions have interchangeable parts. The only significant difference is the CPU clock speed. The machine's general design (and performance) is very similar to the 2010 MacBook Pro. A1342 manufacturing was discontinued in early 2012.No-Start / Totally Dead Machine

This is almost always due to liquid ingress through the keyboard. Often times water will kill the keyboard, but everything else will be just fine. The best way to check it out is to remove the back cover and try to start the machine by briefly shorting the jumper pads with a pair of steel tweezers. When shorted for about 1 second, the fan should spin up and the machine should boot as normal.The startup jumper pads vary by logic board version, but there are two small square solder pads near the keyboard connector.

| |||

| Jumper Pads, used for starting without a working keyboard |

|

| Jumper Pads, on a later logic board |

Unexpected sleeping

Do not stack two A1342 MacBooks on top of one another when in use - you'll cause them to go to sleep. The sleep magnet on the lid will trigger the sensor on the other laptop. The sleep sensor is located next to the headphone port.Reliability issues / Crashing / Kernel Panics

Assuming it isn't software, crashing or poor reliability problems is very likely due to bad memory.Note that these MacBooks only like PC3-1066 (aka 8500) memory. If you have faster memory installed, you'll very likely have severe reliability problems.

Whenever changing or replacing RAM, I use a memtest86 boot USB stick to do a full memory test. It takes about 3.5 hours to test 4 GB of RAM. 8 GB of RAM will take about 7 hours to test, and 2 GB of RAM will take about one hour and 45 minutes. Note that some fraudulent vendors mis-label their RAM products, so just because it says "8500" doesn't mean it is.

Alternatively, you can use a "full test" through Apple Diagnostics (option-D at boot for 2010 models, or with boot media for 2009 models). This is OK, but not as effective as Memtest86.

Keyboard Electronics

- The power key is part of the keyboard.

- The keyboard is very sensitive to water ingress.

- A water-damaged keyboard may detect no key presses, some key presses, or chaotic key press behavior.

- If the keyboard is water damaged, or if the keyboard cable is damaged, the easiest repair (but not the only repair) is to replace the top case.

- I have never been able to repair water-damaged keyboard electronics.

- Other keyboard failure modes:

- It is easy to mistakenly dislodge the keyboard cable when changing the battery. If you have a no-start condition, or bizarre keyboard function, check the cable - maybe the cable is askew or has been dislodged.

- The keyboard will not properly work without a working trackpad. I'm not sure why. If your keyboard seems weird, check the trackpad.

Keyboard Keycaps

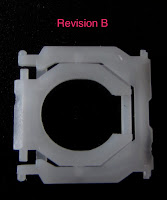

- There were at least two different US keyboards made for these machines. They use different keycaps

- Electronically and from the user's perspective, these US keyboards look identical.

- The primary (important) difference between these two US keyboards is the keycap scissor attachment mechanism.

- The scissors, keycaps, and underlying key attachment deck are different.

- I call the two different keyboards "hook" and "hole", as that's the primary difference of how the scissors attach - via little metal hooks or little metal holes.

- Replacement keycaps may not fit if you don't know the key attachment style you have and what keys/scissors you're buying.

- I'm not sure when the change took place, or if it was due to different suppliers.

- The arrow keys are not the same size as the function keys :-(

- I don't know much about non-US keyboards, but obviously they use a different top case.

Keyboard Replacement while Retaining the Top Case

- The A1342 keyboard electronics were not designed to be separated from the top case. So it is a lot of work to replace the keyboard of a top case. It is easiest to simply replace the entire top case assembly, which includes the keyboard electronics and the top case.

- Some people do want to retain their top case but replace its keyboard. I do not bother to do this unless the top case and the plastic keyboard backplate are in top-notch condition.

- The keyboard can be removed from the top case by:

- Removing the plastic keyboard backplate from the top case. This involves carefully breaking the very strong epoxy bonds around the entire perimeter of plastic keyboard backplate.

- Removing the keyboard by shearing off the 60 or so plastic posts that connect the keyboard with the top case. This is easily done with a sharp x-acto blade.

- Replacement A1342 keyboards are available.

- A real A1342 keyboard is white, and has the power button cable that goes from the eject key to the right, and then up. The holes on the keyboard deck are large enough for the plastic posts.

- A fake A1342 keyboard has a power cable that goes up from the eject key, and then right. Also, the holes on the keyboard deck are smaller, as they are sized for screws and not plastic mounting posts.

- Note that these "fake" A1342 keyboards are actually 13" MacBook Pro keyboards with white keycaps.

- I advise that one doesn't pay any premium for a fake A1342 keyboard. Save some money and just get a black MBP keyboard instead.

- The 13 inch MacBook Pro keyboard does fit, both electronically and physically. These are generally much less expensive than keyboards sold specifically for the A1342. My primary A1342 has a MBP keyboard. Like the "fake A1342" keyboards:

- The power button routing is different

- The attachment holes are smaller

- The A1342 does not support a backlight.

- Since the A1342 uses a lot of epoxy and plastic to fasten the keyboard to the top case, a retrofit will have to recreate that. But don't be too sloppy - misplaced epoxy can impede reassembly.

| ||

Scissor type A is attached by hooks

|

- Failing batteries that are beginning to swell should be removed immediately to prevent permanent damage to the top case, trackpad, or other components.

- It is easy to mistakenly dislodge, distort, or tear the keyboard cable when changing the battery. Take care.

- Some aftermarket batteries have a very long power cord that impedes installation. Sometimes theses "stupidly long" wires can be carefully pushed back into the battery housing.

- If the keyboard or power button doesn't work after a battery change, check and/or reseat the keyboard cable.

- Operating without a battery can impact performance. I noticed this with High Sierra on a late-2009. I speculate the same behavior exists on the mid-2010.

Trackpad

- The keyboard will not work properly without a working trackpad installed.

- An unreliable trackpad should be replaced. I don't know why they sometimes go bad, perhaps water damage?

Logic Board

- A late-2009 logic board will fit in a mid-2010 case, and vice-versa.

- All the parts between a late 2009 and mid-2010 are interchangeable. The only notable difference is the speed of the logic board.

- Logic boards are most likely to be damaged via water ingress or connector damage (poor disassembly)

- The fan is normally robust. I have never seen a fan failure.

- On a newly acquired A1342, I usually remove the logic board and remove all the dust and other junk that ends up in there.

DVD Drive

- DVD drives almost always fail due to foreign matter being put in the slot.

- Carefully opening the DVD drive (via tape and screws) and removing the debris almost always addresses a non-working DVD drive.

- I rarely see a DVD drive with a failure caused by something other than removable foreign matter.

Hard Drive

- Almost any 2.5 inch SATA drive will fit into these Macs

- Many of the drives supplied by the factory are 1.5Gb SATA I. An upgrade to a 3.0 Gb SATA II drive will help with performance. Note that the A1342 not have 6.0 Gb capability - installing a SATA III drive will normally result in SATA II performance.

- A SATA II or III hard drive, or an SSD will greatly improve performance.

- The drive cushioning mechanism changed over time, but it's a very minor change.

- APFS-partitioned disks will not boot in a machine that doesn't have modern firmware. Instead, the "?"-Folder will appear. Use a modern OS installer (High Sierra) to install the latest firmware.

Display

- The display panel has no glass overlay, so scratches on the display are "permanent".

- Opening the display's case to replace the LCD is a huge pain.

- Be very clean so you can "reuse" the adhesive

- All that black tape around the LCD is to prevent backlight bleed. It should be replaced.

- The display panel is common with some similar-vintage 13 inch MacBook Pros.

- Cracks in the plastic housing near the hinges are common. I try to arrest these cracks with epoxy.

- The external display port will not turn on until after the OS has booted. Therefore, operating an A1342 without a working display will require a MacOS boot device.

- Is there firmware way around this? I feel there may be.

- It may (or may not) be reasonably possible to replace the white bezel with a MBP glass. I want to research this. Has anyone tried?

MagSafe Board

These rarely fail, but they can. When they do fail, I think it is due to a knockoff charger sending lousy voltages to the Mac, resulting in a burning out the board, its contacts, and/or melting the top case.- First, make sure you're using a known-good 60 watt or 85 watt genuine MagSafe adapter.

- If that doesn't work, clean the A1342's MagSafe connector.

- If that still doesn't work, the easy fix is to simply replace the MagSafe board, which requires removing the logic board.

Bottom Case

- Yes, the rubber has been known to fail.

- Apple no longer services this problem.

- Reattaching the rubber is not a reasonable possibility

- Alternatives involving removing the rubber from its aluminum backing:

- stick some adhesive feet on the bottom aluminum

- glue upholstery cloth to the bottom aluminum

- apply a rubber paint to the bottom aluminum

- Another more costly solution is to buy a new bottom case.

- Not using the aluminum bottom is stupid and will result in logic board damage.

MacOS

- It is possible to install and run High Sierra on A1342 machines with 2 GB of RAM, but it's really too little RAM to do anything of substance. Therefore, I recommend at least 4 GB of RAM.

- The High Sierra installer may induce a firmware update (for APFS boot)

Performance

Here are my standard steps for performance:- Ensure you have a battery installed. A missing or defunct battery will negatively impact performance.

- Install 8 GB of 8500 RAM (2 x 4 GB). However, 4 GB should be fine.

- Install a name-brand SSD

- Reset PRAM/NVRAM/SMC

- Do a fresh OS install. I use High Sierra

- Enable TRIM in the OS